- Laser marking compared with the advantages and disadvantages of traditional processing

- Reduce the vehicle PCB defect rate of the six major methods

- Why should the PCB board "paste gold"

- PCB hole without copper bad analysis

- Some small principles of PCB copying process

- Double-sided Process

- Multi Version Technique

- Process technology index

- Assurance process

- Management System

- The Inspection and Test

- Printed circuit boards introduce common standards

- PCB design: to reduce noise and electromagnetic interference 24 tips

- Factors affecting impedance PCB processing

- Circuit board gold-plated zedoary relevant comparison

- The difference between gold and gold-plated PCB board Shen board

- PCB circuit board inspection and prevention of short circuit

- The hole broke, the hole wall with copper particles, there are copper, I would like to ask that a few pots of medicine out of the question?

- How to maintain the circuit board to extend the service life

No copper in the hole belongs to the functional problem of pcb. With the development of technology, the PCB precision (aspect ratio) requirements are getting higher and higher. It not only brings troubles to the PCB manufacturer (the contradiction between cost and quality), but also gives downstream customers Buried a serious quality hazard! Here is a simple analysis of this, I hope to have some inspiration and help to the relevant colleagues!

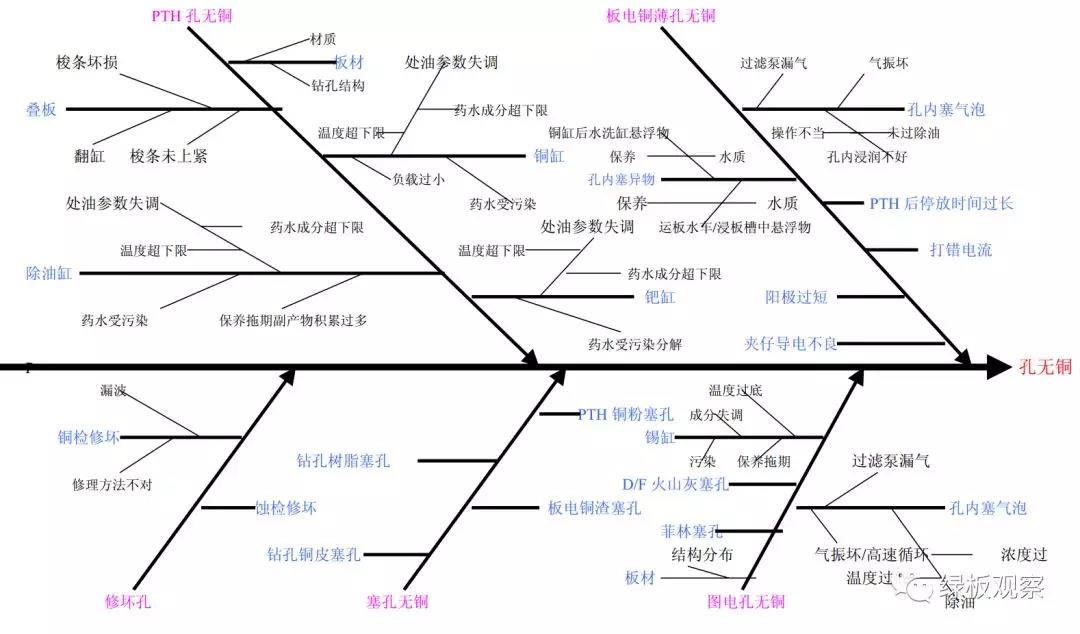

2. Fishbone diagram analysis

3. Classification and characteristics of copper without holes

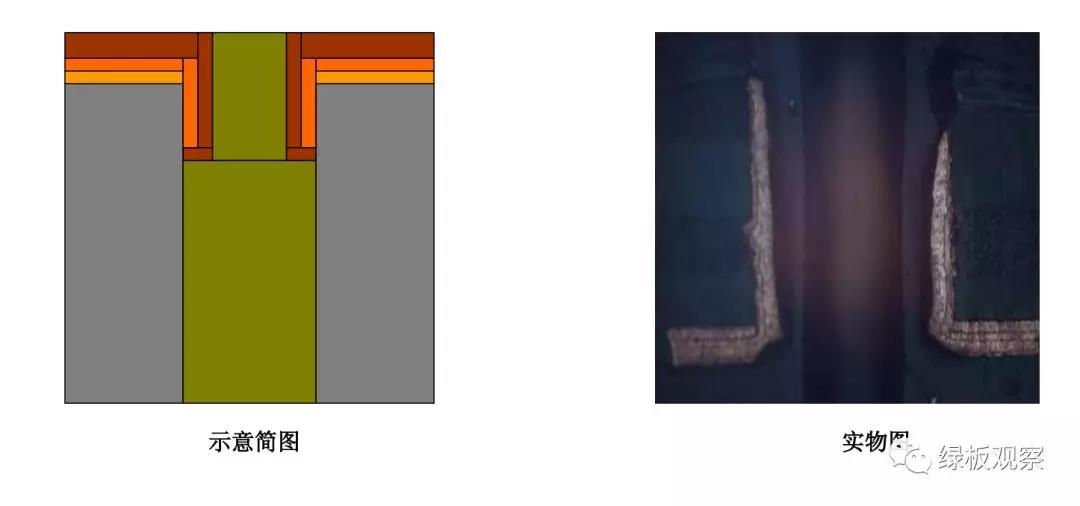

1. There is no copper in the PTH hole: the electric layer of the copper plate is even and normal, and the electric layer in the hole is evenly distributed from the opening to the fracture. After the electric diagram, the fracture is covered by the electric layer.

2. Plate copper thin hole without copper:

(1) The whole plate is made of copper and has no copper. The copper and copper plates are very thin. After the micro-etching, the majority of the copper in the middle of the hole is etched away. The electrical layer is encased;

(2) The inner copper plate of the hole is copper-free—the electric layer of the copper plate is even and normal, and the electric layer inside the hole is declining from the hole to the fracture, and the fracture is generally in the middle of the hole. Copper layer left

The right uniformity and symmetry are better, and the fracture is encased by the electrical layer after the electric diagram.

3. Repair the hole:

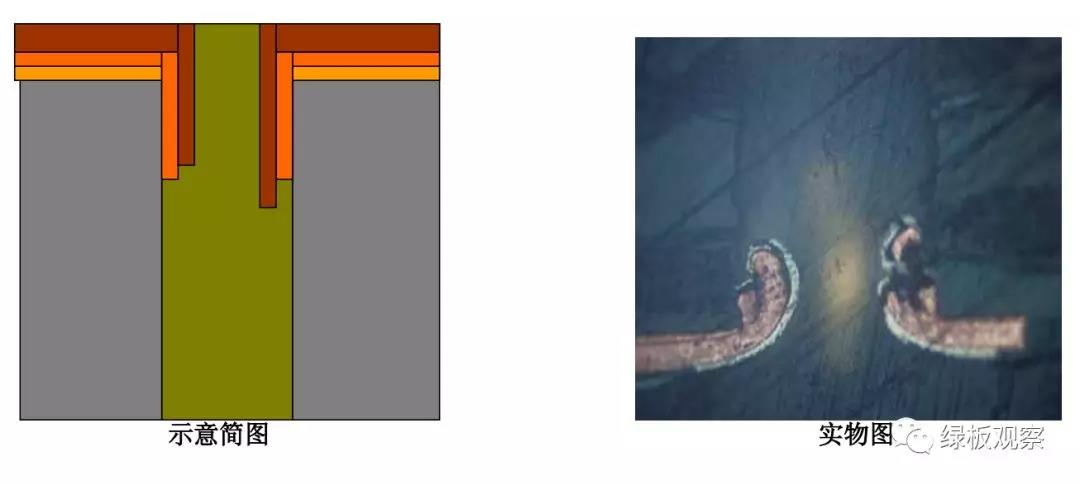

(1) Bronze overhaul bad hole--The copper layer of the copper plate is even and normal, the electric layer of the copper plate has no tendency to pull the tip, the fracture is irregular, and the hole may also appear in the middle of the hole, which often appears on the hole wall. The rough bumps are not good, and the fracture is covered by the electrical layer after the electric diagram.

(2) Corrosion inspection and repair hole---The copper layer of the copper plate is even and normal, the electric layer of the copper plate has no tipping tendency, and the fracture is irregular. It may appear in the middle of the hole and may appear in the hole wall. Bad bumps and other defects, the electrical layer of the fracture does not enclose the electric layer.

4. There is no copper in the plug hole: after the electric etching, there is obvious material stuck in the hole, most of the hole wall is eroded, and the electric layer is not wrapped in the electric layer at the fracture.

5. There is no copper in the figure hole: the electric layer of the figure is not covered by the electric layer. The thickness of the electric layer and the electric layer are uniform, and the fracture is even; the electric layer is pulled until the disappearance. The layer continues to extend beyond the electrical layer for a distance and then disconnects.

Fourth, improve the direction:

Fourth, improve the direction:

1. Operation (upper and lower boards, parameter setting, maintenance, abnormal handling);

2. Equipment (crane, feeder, heating pen, vibration, air pumping, filtration cycle);

3. Materials (plates, potions);

4. Method (parameters, procedures, processes and quality control);

5. Environment (variation caused by dirty, chaotic, and miscellaneous).

6. Measurement (pharmaceutical test, copper inspection).