Technology

- Laser marking compared with the advantages and disadvantages of traditional processing

- Reduce the vehicle PCB defect rate of the six major methods

- Why should the PCB board "paste gold"

- PCB hole without copper bad analysis

- Some small principles of PCB copying process

- Double-sided Process

- Multi Version Technique

- Process technology index

- Assurance process

- Management System

- The Inspection and Test

- Printed circuit boards introduce common standards

- PCB design: to reduce noise and electromagnetic interference 24 tips

- Factors affecting impedance PCB processing

- Circuit board gold-plated zedoary relevant comparison

- The difference between gold and gold-plated PCB board Shen board

- PCB circuit board inspection and prevention of short circuit

- The hole broke, the hole wall with copper particles, there are copper, I would like to ask that a few pots of medicine out of the question?

- How to maintain the circuit board to extend the service life

The hole broke, the hole wall with copper particles, there are copper, I would like to ask that a few pots of medicine out of the question?

Location:Home > Technology

Copper process if the hole broke, hole wall with copper particles, there are copper, I would like to ask that a few pots of medicine out of the question? What is SAP process?

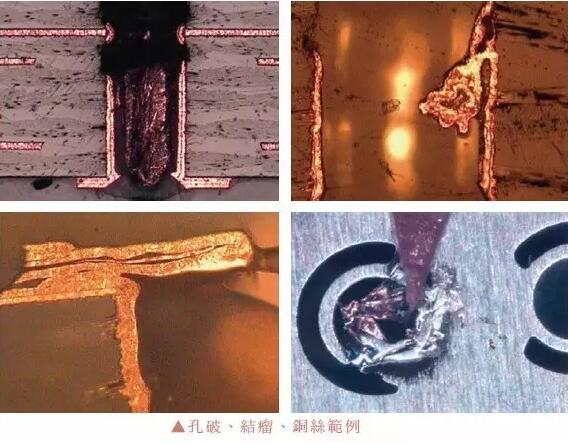

General industry defined a copper, refers to the addition of glue residue, chemical copper, the whole plate plating the three processes as a whole. Hole hole within the hole broken, there are copper particles and copper wire, these problems are often not a copper problem, but the chemical copper precipitation or in addition to the problem of rubber residue process. In the process of removing the residue, the circuit board will go through the leavening agent, oxidant, reducing agent three syrup treatment procedures. If the aging of the syrup during the restoration process, may allow the permanganate residue in the hole wall to remove incomplete. This circuit board when entering the chemical copper process, will be micro-eclipse of the attack and produce local shedding, this time the active agent to establish the active layer will be destroyed and lead to poor growth of chemical copper hole.

Of course, the chemical copper process itself may also produce hole break problems, such as: chemical copper activity is insufficient, the hole depth is too high chemical copper can not be handled, the use of pore and palladium colloid problems, which will also affect the quality of the hole wall. If the drilling quality is poor, hole break is more likely to occur, especially if the hole wall is too thick will lead to poor cleaning, residual liquid affect the chemical copper precipitation and other issues, it is particularly easy to hole broke. As for the occurrence of copper particles, copper and other plating problems, the more common problems to the poor grinding, chemical copper rough and other factors are more common. In improving the chemical copper, it is feasible to improve the washing, the integrity of the pail holder and the replacement of the liquid and so on. In particular, it is necessary to avoid mixing the chemical copper micro-erosion with the stripper, which is often found in the foundry Workplace limited factory occurred. When the two mix, the stripper treatment of residual colloids will be precipitated in the hole, resulting in hole wall roughness. From this point of view, to eliminate such rough problems, not only should avoid the tank mix, but also pay attention to the palladium colloid and washing filter system, the only way to make the hole wall rough chance to a minimum.

The industry can also consider the use of direct plating processes in the permissible conditions of the product. This process does not have a palladium colloid problem, but some systems are limited by the use of such technology because of the circuit board structure and past historical experience. Consider the part. Shadow (Shadow), Black Hole (BlackHole) and other processes, are representative of this technology, and perhaps also improve the function of the hole wall copper particles.

SAP full name is "SemiAdditiveProcess", because the general line production is divided into full etching and partial etching part of the line plating two practices. Part of the etching of this practice, the line production capacity is strong, you can make smaller lines. So the general circuit board external lines, if the line design is thin, it may consider the use of SAP process production line. In recent years, line production requirements more and more sophisticated, so part of the circuit board production using the whole chemical copper-based approach, and most of the current industry called the so-called SAP process is specifically refers to such practices.

General industry defined a copper, refers to the addition of glue residue, chemical copper, the whole plate plating the three processes as a whole. Hole hole within the hole broken, there are copper particles and copper wire, these problems are often not a copper problem, but the chemical copper precipitation or in addition to the problem of rubber residue process. In the process of removing the residue, the circuit board will go through the leavening agent, oxidant, reducing agent three syrup treatment procedures. If the aging of the syrup during the restoration process, may allow the permanganate residue in the hole wall to remove incomplete. This circuit board when entering the chemical copper process, will be micro-eclipse of the attack and produce local shedding, this time the active agent to establish the active layer will be destroyed and lead to poor growth of chemical copper hole.

Of course, the chemical copper process itself may also produce hole break problems, such as: chemical copper activity is insufficient, the hole depth is too high chemical copper can not be handled, the use of pore and palladium colloid problems, which will also affect the quality of the hole wall. If the drilling quality is poor, hole break is more likely to occur, especially if the hole wall is too thick will lead to poor cleaning, residual liquid affect the chemical copper precipitation and other issues, it is particularly easy to hole broke. As for the occurrence of copper particles, copper and other plating problems, the more common problems to the poor grinding, chemical copper rough and other factors are more common. In improving the chemical copper, it is feasible to improve the washing, the integrity of the pail holder and the replacement of the liquid and so on. In particular, it is necessary to avoid mixing the chemical copper micro-erosion with the stripper, which is often found in the foundry Workplace limited factory occurred. When the two mix, the stripper treatment of residual colloids will be precipitated in the hole, resulting in hole wall roughness. From this point of view, to eliminate such rough problems, not only should avoid the tank mix, but also pay attention to the palladium colloid and washing filter system, the only way to make the hole wall rough chance to a minimum.

The industry can also consider the use of direct plating processes in the permissible conditions of the product. This process does not have a palladium colloid problem, but some systems are limited by the use of such technology because of the circuit board structure and past historical experience. Consider the part. Shadow (Shadow), Black Hole (BlackHole) and other processes, are representative of this technology, and perhaps also improve the function of the hole wall copper particles.

SAP full name is "SemiAdditiveProcess", because the general line production is divided into full etching and partial etching part of the line plating two practices. Part of the etching of this practice, the line production capacity is strong, you can make smaller lines. So the general circuit board external lines, if the line design is thin, it may consider the use of SAP process production line. In recent years, line production requirements more and more sophisticated, so part of the circuit board production using the whole chemical copper-based approach, and most of the current industry called the so-called SAP process is specifically refers to such practices.

In fact, where the line plating method should be called SAP process, but their bottom copper thickness difference only, but the current comparison of the industry that only copper pure copper process should use such a call. In addition, in the field of loading and unloading board, the industry also part of the use of ultra-thin copper production line, this time and added a different title "M-SAP", the M refers to the metal, is the meaning of copper, And then pure chemical copper base, but ultra-thin copper. Above for reference only.